Packaging, Could it be more sustainable?

Plastic bag we use in textile industry is one of the most common accessories as addition to the product and we wanted to understand the possible sustainable solutions on this area to clarify if it is true what we know or heard and what are the options.

Recycled or Recyclable?

The most important detail is plastic bags can be recyclable up to 7 times, further the recycle process will continue and plastic can use as a garbage bag and then still have usage in industrial materials .

Based on this information all packaging materials can be promoted as Recyclable.

The most powerful change could also turn all transparent plastic bags, courier bags and shopping bags into recycled material and all these packages will be still recyclable.

Fact & Suggestions

- By recycling we reduce the petrol based row-material usage

- Reduce the wastage in the production circle

- Recycled transparent bags could be a little dull and less transparent and to be able to use our own bags to recycle ; either there should not be any print on the product or prints to be in white

- Recycled shopping bags possibly have a little smell on them which would not pass to the products and could also perfumed

- Recycled material can be tested to identify

Recycled bags are available in the Turkish market in, it’s not a new technology for the plastic world and suppliers also use their own second hand qualities and wastes into the recycling.

The main concern on the plastic bag usage is to be able to organize the collection. Knowing the fact that on textile products usage of the plastic bags are in every stage of the products, one of our suppliers suggesting to develop an application, which could also embedded to current application of the brand, and organize customers to return their plastic bags to the agreed collection points and then they will collect all these used plastics to turn to shopper bags and courier bags again for the brand.

We can work on specific projects and create awareness for the customers as well as reducing our carbon footprint.

Bioplastic bags

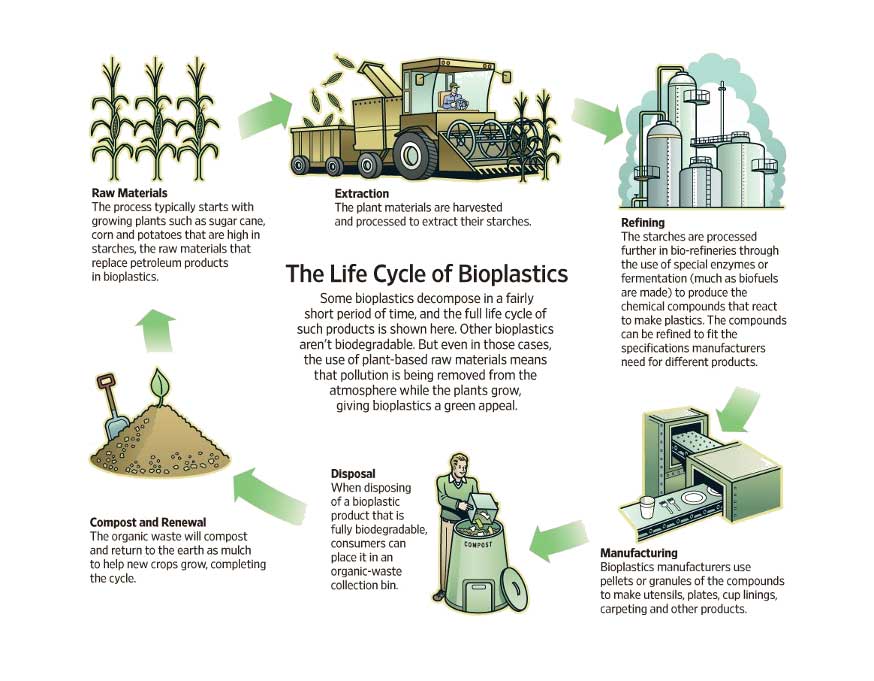

Bioplastics are plastic materials produced from vegetable fats and oils, plant and vegetable starches or from agricultural products by using microorganisms.

We can categorize bio plastics into two section, bio based plastics and biodegradable plastics. So; not all the bioplastic materials can be considered as biodegradable.

Biodegradable plastics can also look under 2 categories; synthetically produced and petroleum based which are not compostable and produced with natural row materials and compostable.

We will look into biodegradable and also compostable bio-plastic bags which are becoming popular in the industry.

Bio Degradable & Compostable Bio-Plastic Bags

Due to form of the product and usages replacement of the plastic bags even we call these products as plastic; it’s not a plastic material.

These products are produced with the starches of sugar cane, corn and potato. Main row material is starch which is almost 100% coming from eatable products and also sustainable compare to petrol based plastics. These products need to collect and send to composting facilities to turn into fertilizer to finish their lifecycle.

Facts & Suggestions

- Coming from almost 100 % row material, these products can be eaten by the insects in the soil but they need controlled and conditioned facilities to turn into soil as compost. After completing their life cycle they don’t left any toxic and harmful substances, be part of soil and nature, prevent environmental pollution.

- Reducing the petrol based row material usage and eliminate the waste created

- Even the row material is sustainable and don’t have petroleum based carbon, we are using eatable products coming from controlled farms to make bags and we should think deeply how this will affect the people in the world living on the edge of starving.

- Starch based products are not transparent; they have a dull white look and a little flour smell on them.

- Starch based products, based on the availability of the row material, are not consistent in color and transparency.

- Can be stored maximum of 6 months and shelf life is 18-24 months.

In Turkey we have suppliers producing both recyled materials with RSC and biodegradable and compostable producs with (TÜV) EN13432 sertificates .

We are happy to share samples and further details.